Top 5 Common Safety Incidents in Industries and How Technology Can Prevent Them

Problem Statement: Addressing Safety Gaps in Industrial Environments

Introduction:

Industrial environments are prone to safety incidents that can lead to severe consequences. Traditional safety measures often fall short of ensuring real-time monitoring and compliance.

Key Challenges:

Non-Compliance with PPE Protocols

Workers neglecting safety gear put themselves at significant risk.

Delayed Hazard Detection

Manual monitoring systems often fail to detect risks like spills or equipment malfunctions promptly.

Overlooked Machinery-Related Risks

Lack of automated monitoring leads to increased accidents during equipment use.

Fire Hazards

Inefficient fire detection systems can escalate small incidents into major disasters.

“AI-powered safety systems provide a proactive approach to preventing accidents. With real-time monitoring and automation, industries can achieve safer workplaces and reduce risks significantly.”

Solution Title: Revolutionizing Industrial Safety with AI

AI-driven safety solutions address the root causes of incidents by providing real-time monitoring and automated alerts.

Solution Key Modules:

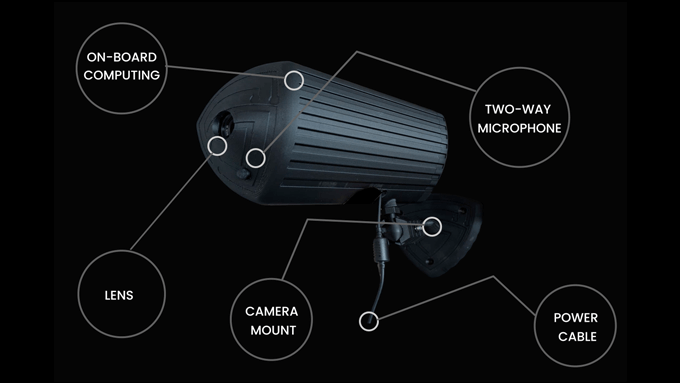

- PPE Detection: Ensures workers wear safety gear using AI-powered cameras and sends instant alerts for non-compliance.

- Hazard Monitoring: Detects spills, equipment malfunctions, and other risks in real time.

- Fire Detection: Identifies early signs of fire hazards for faster intervention.

Conclusion: Safer Workplaces, Smarter Solutions

Impact Highlights:

- Increased Compliance: Automated systems ensure adherence to safety protocols.

- Proactive Risk Mitigation: Early detection of hazards prevents accidents.

- Improved Worker Safety: Reduces the risk of injuries in high-risk environments.

- Cost Savings: Minimizes operational disruptions caused by accidents.

Related Blog

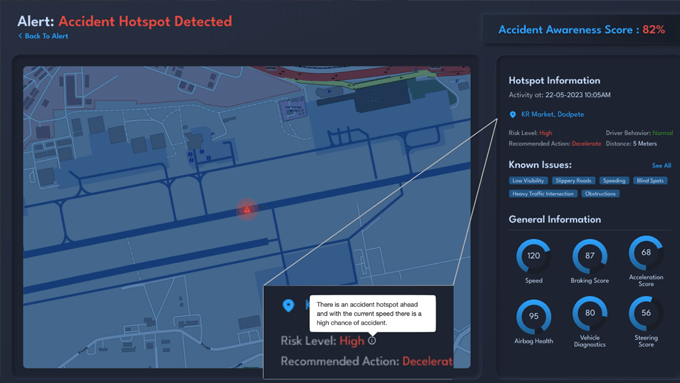

Revolutionizing Road Safety: AI-Powered Solutions in the Automotive Industry

Enhancing IT Park Security and Operations with Adaptive AI-Powered Surveillance