Revolutionizing Industrial Operations with Barcode Automation

Problem Statement: Bridging Efficiency Gaps in Industrial Operations

Introduction:

Industrial environments often face inefficiencies in manufacturing and logging due to manual errors and outdated systems. Barcode automation offers a modern solution to streamline operations.

Key Challenges:

Manual Errors

Human involvement increases the chances of mistakes in data entry and tracking.

Time-Intensive Processes

Traditional systems slow down production and logistics.

Inconsistent Data Logging

Inefficient tracking leads to gaps in inventory management.

High Operational Costs

Manual processes require extensive resources.

“Barcode automation brings a new level of efficiency and accuracy to industrial operations, helping businesses achieve greater productivity and reliability.”

Solution Title: The Power of Automation in Industry

By automating operations with barcode scanning, industries can eliminate inefficiencies and improve overall accuracy.

Solution Key Modules:

- Automated Data Logging: Tracks inventory and operations seamlessly.

- Real-Time Monitoring: Provides instant updates for inventory and production lines.

- Error Reduction: Minimizes mistakes in tracking and reporting.

- Scalability: Adaptable for businesses of all sizes and sectors.

Conclusion: Smarter, Faster, Better Operations

Impact Highlights:

- Increased Accuracy: Reduces errors in inventory and production tracking.

- Faster Processes: Speeds up operations with real-time automation.

- Cost Savings: Lowers resource requirements and operational costs.

- Improved Productivity: Enables seamless workflows and better output.

Related Blog

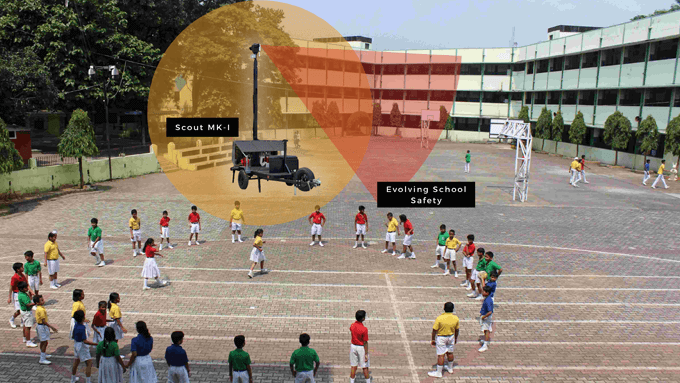

Revolutionizing Border Security with Intelligent CCTV based Smart Monitoring